Nokuba yimoto entsha okanye endala, ukugcinwa kwepeyinti yemoto bekusoloko kuyinto exhalabisayo kubanini bemoto malunga neprojekthi ebalulekileyo, uninzi lwabahlobo bemoto bebesoloko bengenamdla minyaka le, ukugquma okuqhubekayo, ukugquma ngekristale, andazi ukuba uyazi na ukuba iprojekthi yokulungisa ipeyinti eyahlukileyo ibisasazeka kancinci kancinci kwimarike yeemoto - ifilimu yokukhusela ipeyinti.

Ngaba nawe ufuna ukufaka i-PPF entle emotweni yakho? Namhlanje ndiza kwabelana nawe ngenkqubo echanekileyo yokusebenzisa i-PPF, ukuze ukwazi ukuphucula amava okusebenzisa i-PPF ngelixa ukhusela imoto yakho!

Yonke inkqubo

1. Ukuqinisekiswa kwerisithi yokwakha: Ngaphambi kokuba ufake ifilimu, qiniseka ukuba irisithi yokwakha iphawulwe ngokucacileyo ngophawu, ixesha lewaranti, ixabiso kunye nezinye iimfuno, kwaye uqinisekise ukuba kukho iphepha lokugcina.

2. Ukuhlolwa kwemoto: jonga yonke ifilimu yemoto ukuba akukho mikrwelo, kuquka ipeyinti, izibane zemoto, amavili, iindawo zokuhombisa, njl.njl., ukuqinisekisa ukuba imoto ikwimeko entle ngaphambi kokuba ifilimu isuswe.

3. Ukuhlolwa kokuvula ifilimu: vula ibhokisi apho ukuze ujonge ifilimu, ukuqinisekisa ukuba umgangatho kunye nohlobo lwefilimu luhambelana nekhethiweyo, ukuthintela ubusela.

4. Inkqubo yokuncamathisela: amaqabane angcono ukuba abekho ukuze abukele inkqubo yokuncamathisela. Ukuba ixesha lide kwaye awukwazi ukubakho ukuze ubone, ungavumela ivenkile ukuba ikubonelele ngevidiyo yokwakha, ulandelelwano olukwi-intanethi lunokwenzeka.

5. Yithathe imoto: ngaphambi kokuba uyithathe imoto, qiniseka ukuba ujonge ukuba imiphetho kunye neekona ezisongiweyo zisendaweni yazo, nokuba ijakethi yemoto ithe tyaba ayinamabala, akukho zimpawu zeglu, amabala othuli, amabala amanzi, njl. kufuneka zihlolwe ngononophelo.

Iingcebiso

1. Ukulungiselela: Ngaphambi kokuba ufake ifilimu, qiniseka ukuba umphezulu wemoto ucocekile kwaye awunalo uthuli, igrisi okanye olunye uthuli. Kungcono ukusebenza ngaphakathi okanye kwindawo ekhuselekileyo ukunciphisa impembelelo yezinto zangaphandle kwinkqubo yokufaka ifilimu.

2. Nciphisa uze usike: Faka ifilimu yokukhusela ipeyinti emanzini uze wongeze isicoci okanye isepha encinci ukuze kube lula ukuyihambisa nokuyilungisa. Emva koko yomisa umphezulu wesithuthi ngelaphu elithambileyo.

3. Ukuncamathelisa: Beka ifilimu ngononophelo kumphezulu wesithuthi kwaye ulungise indawo usebenzisa amanzi avela kwibhotile yokutshiza ukuqinisekisa ukuba ihambelana nomsebenzi womzimba. Kwangaxeshanye, kuphephe ukudibana phakathi kwefilimu nomphezulu oncamathelisayo.

4. Ukukhupha umoya: Sebenzisa i-squeegee ekhethekileyo okanye i-squeegee ethambileyo, susa ngobunono amaqamza omoya embindini wefilimu uye emacaleni. Oku kuya kunceda ifilimu ukuba inamathele ngakumbi emzimbeni wemoto.

5. Ukucheba: Ukuba ifilimu ayingeni kakuhle okanye ineebhamuza zomoya kwiindawo ezithile, sebenzisa i-heat gun okanye i-hair dryer ukuze uyifudumale kancinci uze uyichebe nge-squeegee.

6. Uhlolo Olupheleleyo: Emva kokugqiba ukunamathela, hlola ngononophelo umphezulu wefilimu ukuze ubone amaqamza okanye imibimbi. Ukuba zikhona, ungasebenzisa isixhobo sokuzisusa ngononophelo.

7. Ukulungisa: Linda ifilimu yome, uze uyisule kancinci ngelaphu elithambileyo ukuqinisekisa ukuba umphezulu uthambile, uze uphephe ukuhlamba imoto okanye ukuyibeka emanzini emvula kwiiyure ezingama-24 ezizayo ukuqinisekisa ukuba ifilimu iqinile ngokupheleleyo.

Uhlolo oluphambili

1. ibha yangaphambili: ayinakudityaniswa, ifilimu yonke iya kujongeka intle xa incamathiselwe.

2. Isiphatho socango lwangaphambili: isiphatho kulula ukusityeshela, kufuneka sinqunyulwe kakuhle, asibonakali ngathi sipeyinti eqhaqhazelisayo, ebonakala ngaphandle.

3. Ucango: ijakethi yemoto kufuneka incamathiselwe emnyango, kungenjalo kuya kuba lula ukuyigoba nokuveza ipeyinti ngaphandle.

4. Iziketi ezisecaleni: yonke ifilimu ilaminethiwe, akunakubakho kudityaniswa.

5. Imithungo: ifilimu kufuneka incamathiselwe kwimithungo, umhlophe awuvumelekanga.

6. Isango lokutshaja: vula isango lokutshaja alinakuvezwa kwipeyinti, ifilimu yonke ayophukanga.

7. Banga iwaranti ye-elektroniki: ifilimu elungileyo ifuna ijazi lemoto elisemgangathweni ophezulu kunye nobugcisa obuqinileyo kunye nomphathi wokwakha. Ikhowudi yewaranti ye-elektroniki ibaluleke kakhulu ukuqinisekisa ukuba ikhowudi yebhokisi yefilimu, ikhowudi yesilinda yefilimu, ikhowudi yewaranti ye-elektroniki iyahambelana, ukuze uphephe ukunamathela kwifilimu yobuxoki. Khumbula ukukhetha uphawu oluqhelekileyo kunye neevenkile ezigunyazisiweyo.

Okokugqibela, kukho ezinye iimpawu zeemoto ezineempawu zazo ezichasene nobuxoki, amaqabane anokunika ingqalelo ngakumbi kwezi mpawu ezichasene nobuxoki xa ekhetha i-PPF.

Qinisekisa nevenkile ukuba ibuyela kwixesha lokuhlolwa kwevenkile: kuba iglu ethintela uxinzelelo idinga ixesha lokulungiswa, ngoko ke kuphephe ukuhlamba imoto kwaye usebenze ngesantya esiphezulu kwiveki. Ukuba kukho ingxaki ngemiphetho, buyela evenkileni ngexesha elifanelekileyo ukuze ujonge ukuqinisekisa ukuba isiphumo sefilimu asinasiphako!

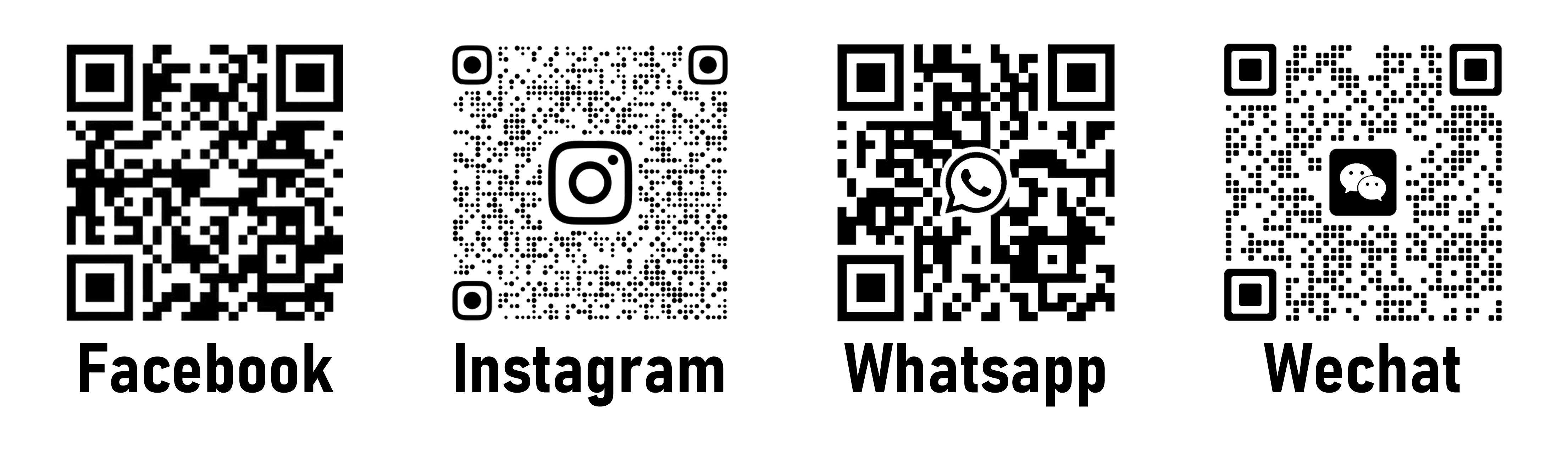

Nceda uskene ikhowudi ye-QR engentla ukuze unxibelelane nathi ngokuthe ngqo.

Ixesha leposi: Epreli-27-2024